XPS Insulation Board Production Line

- Home

- Products

- Insulation Materials Machinery

- XPS Insulation Board Production Line

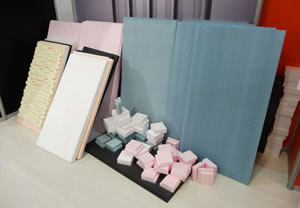

Introduction of XPS

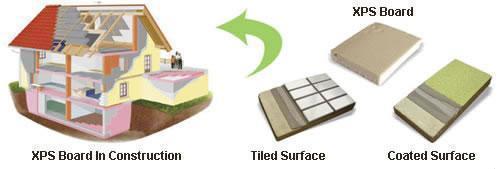

XPS (extruded polystyrene) insulation board--- a kind of new insulation material is a high quality polystyrene foam product characterized by smooth skin with a closed-cell structure that looks like a mass of uniform bubbles with common walls between them. There are few, if any, voids between the cells, top and bottom skin. Comparing with other traditional heat insulation materials, such as EPS (Expand Polystyrene Foam), PU (Polyurethane Foam) and Rock wool, XPS is improved in terms of insulation, moisture-proof, compressive strength, durability, convenient installation and low cost. As an ideal heat insulating material, XPS is widely applied in heat preservation and insulation systems, moisture-proof and obstruct systems, with promising potential market.

Advantages

1. Competitive Price

The XPS insulation board production line comes with updated technology and high quality. Compared with the XPS insulation board machinery with the same capacities from Europe, our product is much cheaper. In addition, this production line can help users realize low-carbon economy.

2. Wide Range of Raw Material

The building material production line uses recyclable materials for production, such as EPS, XPS, GPPS, as well as virgin GPPS, which is conducive to the environment protection and the cost reduction during XPS board production. However, XPS insulation board production line from European countries only employs virgin GPPS as raw material.

3. Environment Protection

Taking LPG, butane and/or CO2 as well as ethanol as the foaming agent, the manufacturing process and the insulation board cause little HCFC or HFC, preventing the air from being polluted.

4. Flexible Configuration and Wide Production Capacity

The first extruder can be designed with single or twin screws. With different screw diameters and sizes, the first extruder and the second extruder can be flexibly configured to realize the output from 200kg to 600kg per hour, capable of meeting most of the clients' requirement.

5. Rich Experience

We have rich experience in the production, installation and operation of the XPS insulation board production line. The worldwide application of our product demonstrates our excellence in product manufacture, installation, commissioning, testing, customer training, and after-sales service.

6. Quality Certificates

This construction material machinery is CCC, CE, ASME, GOST compliant.

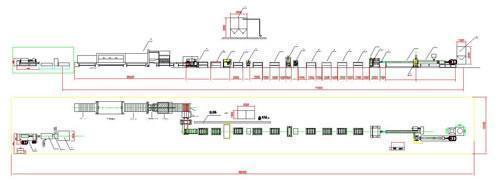

Main Configuration of XPS Insulation Board Production Line

Feeding System / First Extruder / Hydraulic Mesh Exchanger / Second Extruder / Mould / Calibrator / First Haul-off Unit / Longitudinal Cutter / Cross Cutter / Second Haul-off Unit / Controlling System / Packing System / Auxiliary equipments

Technical Parameters of XPS Insulation Board Production Line

| Item | Unit | HIM-X-250 | HIM-X-500 | HIM-X-750 | |||

| Extruder System | - | 1st Extruder | 2nd Extruder | 1st Extruder | 2nd Extruder | 1st Extruder | 2nd Extruder |

| Screw Diameters | mm | 135 | 150 | 75×2 | 160 | 75×2 | 200 |

| L/D Radio | L/D | 30:1 | 33:1 | 30:1 | 40:1 | 30:1 | 36:1 |

| Driving Motor Power | kw | 75 | 55 | 75 | 75 | 90 | 90 |

| Capacity | kg/h | 250-300 | 350-450 | 450-550 | |||

| Product Width | mm | 600 | 600 | 600 | |||

| Product Thickness | mm | 20-100 | 20-100 | 20-100 | |||

| Density | kg/m3 | 30-39 | 30-39 | 30-39 | |||

| Total Power | kw | 260 | 280 | 350 | |||

Layout of XPS Insulation Board Production Line

Compare of Main Insulating Materials

| Item | XPS | EPS | PU | Rock Wool | |

| Thermal Conductivity [w/( m·k)] | At the beginning | 0.030 | 0.041 | 0.02 | 0.044 |

| After three years | ≤0.04 | ≥0.06 | ≥0.06 | ≥0.06 | |

| Compressive Strength (kpa) | When dry | 350 | 80 | 165 | |

| After watering | 350 | 60 | 110 | ||

| Tensile Strength (Kpa/m2) | ≥300 | ≥65 | — | — | |

| Density (kg/m3) | 32~39 | 25~28 | 25~30 | 150~200 | |

| Water Absorption (%)(V/V) | At the beginning | ≤0.76 | ≤8 | ≤6 | ≤5 |

| After three years | ≤1 | ≥40 | ≥40 | ≥40 | |

| Thickness (mm) | 25 | 38 | 21 | — | |

| Volume Stability | Good | Good | Good | Good | |

| Combustibility | B2 | B1 | Noncombustible | ||

| Direct Use | Easy | Easy | Easy | Difficult | |

| Raw Material | 100% new material ~ 100% recycled material |

100% new material |

100% new material |

100% new material |

|

| Cost | Low | Middle | High | Middle | |

| Production Process | Easy | Easy | Complex | Complex contaminative | |

Related Names

XPS Production Line

English

English Español

Español Русский

Русский Français

Français العربية

العربية