Glass Wool Production Line

- Home

- Products

- Insulation Materials Machinery

- Glass Wool Production Line

Brief Introduction of Glass Wool

Glass wool is made of natural ores such as quartz sand, dolomite, feldspar, limestone and so on, which are melted into glass fluid by adding in accessories such as calcined soda and borax and then drawn, blown or thrown into very thin fibers by external force under fusing state and now it is a kind of insulation material with excellent characters.

Main Materials to Produce Glass Wool

| Item | Description |

| Quartz sand | Its main composition is SiO2, content of which is more than 90% |

| Feldspar | It can be classified into potash feldspar albite according to its chemical composition. Al2O3>15%, SiO2<70%, Fe2O3<0.3%, R2O>10% |

| Dolomite | MgO>20%, CaO<32%, Fe2O3<0.15. Dolomite is water-absorbent, so it should be stored in dry places |

| Calcined soda | Na2CO3>98%, NaCl<1%, Na2SO4<0.1%, Fe2O3<0.1% |

| Borax (Na2B4O7.10H2O) | B2O3>35%, Fe2O3<0.01%, Na2SO4<0.02% |

| Limestone | CaO≥50%, Fe2O3≤0.15% |

| Cullet | Broken and non-conforming glass products as well as glass chops made by chilling vitreous fluid in water, whether they are glass scraps produced in production or glass waste rejected in society, all can be used as raw materials for glass |

Features of Glass Wool

As a kind of inorganic fiber, glass wool has the following basic characteristics:

1. Good thermal insulation performance under both high and low temperature.

2. "Statutory incombustible material" --- it neither burns, nor gives off harmful gas.

3. Uniform resilience force.

4. Excellent sound-absorption performance and noise reducing effect.

5. Low moisture absorption rate under humid conditions.

6. Low coefficient of linear expansion.

7. Low aging rate, being able to maintain the original performance after long-time use.

8. Excellent handling characteristics.

Technical Parameters of Glass Wool Production Line

| Item | HIM-GW-3 | HIM-GW-5 | HIM-GW-8 | HIM-GW-10 | HIM-GW-15 |

| Production Capacity (mt/year) | 3000 | 5000 | 8000 | 10000 | 15000 |

| Workshop (L×W) (m) | 75×15 | 85×15 | 90×15 | 95×20 | 100×25 |

| Dimension (L×W×H)(m) | 65×10×14 | 75×10×14 | 80×10×14 | 85×15×14 | 90×20×14 |

| Weight (mt) | 180 | 190 | 200 | 210 | 300 |

| Power (kw) | 630 | 750 | 950 | 1000 | 1300 |

| Power Supply | 220V / 380V, 50Hz | ||||

Specification of Glass Wool Products

| Product | Density (kg/m3) | Dimension (mm) | ||

| Length | Width | Thickness | ||

| Board | 25~100 | 1000~10000 | 500, 600, 630 | 20~100 |

| Felt | 10~28 | 1000~15000 | 1000, 1200 | 30~150 |

| Pipe Cover | Density | Length | Inner Diameter | Thickness |

| 10~18 | 1000 | 18~315 | 30~100 | |

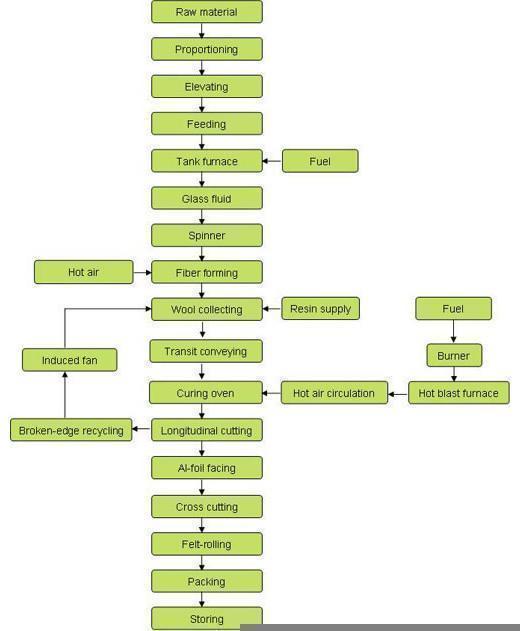

Flow Chart of Glass Wool Production Line

Raw material -> Proportioning -> Elevating -> Feeding -> Tank Furnace -> Glass Fluid -> Spinner -> Fiber forming -> Wool Collecting -> Transit conveying -> Curing oven -> Longitudinal cutting -> Aluminum foil facing -> Cross cutting -> Felt rolling -> Packing -> Storing. And for the detailed information please refer to the following chart:

Related Names

Glasswool Production Line

English

English Español

Español Русский

Русский Français

Français العربية

العربية