Plastic Pipe Extrusion Line

- Home

- Products

- Plastic Machinery

- Plastic Pipe Extrusion Line

Introduction of Plastic Pipe Extrusion Line

Demand of world wide plastic pipe continues to increase annually (source: The Freedonia Group Inc). More and more new applications are forecasted to come up as concerns on environment and energy becoming more compelling.

Drawing upon profuse experience in this field, we have innovatively manufactured a number of state-of-the-art machines and developed a concept which enables our customers to pursue the most while keeping a possibly lowest cost. The Plastic Pipe Extrusion Line from HiSuccess International can use a variety of polymers such as PE, PP, PVC to produce a broad range of plastic pipes with solid quality.

Features of Plastic Pipe Extrusion Line

1. Compact design and flexible layout of the assembly line.

2. State-of-the-art design gives the machine exclusive advantages of high productivity and superb cost efficiency.

3. The extrusion production line can employ single and twin extruder which have a wide range of processing applications by certain slight change and replacements of some parts.

4. Patented technology guarantees products with good homogeneity and plasticity while possessing high performance in reasonably lower melt temperature.

5. Competent for producing a few kinds of plastic pipes such as PE, PVC, PP pipe with diameters range from 16mm to 630mm.

6. Can meet the specific requirements of different customers.

7. All-around technical supports and comprehensive before and after sale services ensure a smooth and care-free operation of this line.

8. A number of adoptions of automation can precisely control the process thus resulting in a solid quality of final products.

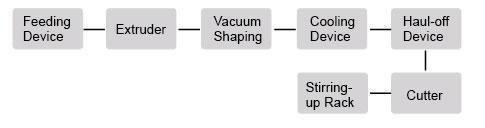

Flow Chart of Plastic Pipe Extrusion Line

Technical Parameters of Plastic Pipe Extrusion Line

1. Typical Single Screw Extrusion Line

| Item | HIM-SJ-60 | HIM-SJ-75 | HIM-SJ-90 | HIM-SJ-120 |

| Extrusion Capacity (kg/h) | 100~200 | 150~250 | 200~300 | 300~400 |

| Diameter of Screw (mm) | 60 | 75 | 90 | 120 |

| L/D Ratio of Screw | 33:1 | 33:1 | 33:1 | 33:1 |

| Extruder Heating Power (kw) | 15 | 15 | 18 | 20 |

| Main Motor Power (kw) | 90 | 110 | 160 | 280~315 |

| Pipe Diameter Range (mm) | Φ20~Φ160 | Φ110~Φ250 | Φ110~Φ400 | Φ160~Φ500 |

| Total Power (kw) | 137 | 188 | 247 | 399 |

| Overall Dimension (L×W×H)(m) | 30×6×4 | 35×6×4 | 38×6×4 | 40×6×4 |

Note: The applicable materials for single screw extrusion production line are PE, PP and etc.

2. Typical Conical Twin Extrusion Line

| Item | HIM-SZ-51 | HIM-SZ-65 | HIM-SZ-80 | HIM-SZ-92 |

| Extrusion Capacity (kg/h) | 100~120 | 200~250 | 350~400 | 500~600 |

| Diameter of Screw ( mm) | 51/105 | 65/132 | 80/156 | 92/188 |

| Extruder Heating Power (kw) | 15 | 24 | 36 | 46 |

| Main Motor Power (kw) | 15 | 37 | 55 | 110 |

| Pipe Diameter Range (mm) | Φ20~Φ160 | Φ50~Φ160 | Φ250~Φ400 | Φ315~Φ630 |

| Total Power (kw) | 61 | 92 | 135 | 203 |

| Overall Dimension (L×W×H)(m) | 30×6×4 | 35×6×4 | 38×6×4 | 40×6×4 |

Note: The applicable materials for conical twin screw production line are PVC, UPVC and etc. Two extrusions from one mould and four extrusions from one mould are also achievable by the conical twin screw production lines.

Plastic Machinery

Plastic (Pipe, profile, Sheet) Extrusion Line

Plastic Injection Machinery

Plastic Blowing Machinery

Plastic Recycled Production Line

EPE-Expandable Polyethylene Production Line

PSP Foaming Sheet Extrusion Line

Related Names

Plastic Pipe Production Line

English

English Español

Español Русский

Русский Français

Français العربية

العربية