Autoclaved Aerated Concrete Production Line

- Home

- Products

- New Building Materials Machinery

- Autoclaved Aerated Concrete Production Line

Introduction of Autoclaved Aerated Concrete (AAC)

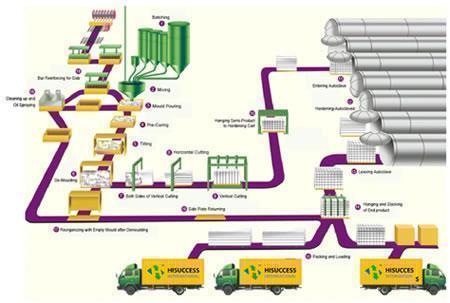

With the obvious advantage of light weight, this Autoclaved Aerated Concrete (AAC) is a multi-cell new construction and building material, which is made from silicon material (silica sand, or recycled fly ash) and calcium material (lime, cement), mixing with foaming additive (aluminum powder), batching with water, the reaction between aluminum and concrete causes microscopic hydrogen bubbles to form, expanding the concrete to about five times its original volume. Through the processes of molding, pre-curing, cutting, evaporating and curing, this building material is then made into the multi-cell silicate product.

Features of Autoclaved Aerated Concrete( AAC)

• Lower density

• Good heat insulation and preservation

• High processibility

• Fire and acoustical resistant properties

• Most prominent advantage: plasticity

Application of Autoclaved Aerated Concrete products

Technical Parameters of Autoclaved Aerated Concrete Production Line

| Item | Unit | HIM-AAC-10 | HIM-AAC-15 | HIM-AAC-20 | HIM-AAC-30 | HIM-AAC-45 |

| Capacity | ×103m3/year | 100 | 150 | 200 | 300 | 450 |

| m3/day | 350 | 500 | 700 | 1000 | 1500 | |

| Block Size | m | 4.0×1.2×0.6 | 4.2×1.2×0.6 | 4.8×1.2×0.6 | 6.0×1.2×0.6 | 6.0×1.5×0.6 |

| Installed Power | kw | 800 | 900 | 1100 | 1300 | 1500 |

| Workshop Area | m2 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Plant Area | m2 | 20000 | 25000 | 30000 | 35000 | 40000 |

Technic Index and Autoclaved Requirements of Autoclaved Aerated Concrete Production Line

| Item | Description | |

| Raw material mixing and pouring cycle | 8 minutes | |

| Base body static curing time | 1.5~3 hours | |

| Static curing temperature: | 40℃ | |

| Strength after static curing | 0.2~0.3Mpa | |

| Base body cutting cycle | 6 minutes | |

| Autoclave pressure | Vacuuming | 0-0.06 Mpa, 0.5hour |

| Rising pressure | 0-1.3 Mpa, 2hours | |

| Working pressure | 1.3 Mpa (temperature 193±5) 7hours | |

| Falling pressure | 1.3 -0 Mpa, 2hours | |

| Raw materials batching rate: | Sand (or Fly Ash) | 69% |

| Lime | 20% | |

| Cement | 8% | |

| Gypsum | 3% | |

| Aluminum powder | 0.074% | |

Note: The accurate raw material batching rate is adjustable according to local raw material.

Related Names

AAC production line | Autoclave aerated concrete production line | Lightweight concrete block production line

English

English Español

Español Русский

Русский Français

Français العربية

العربية