Wood Plastic Composite Production Line

- Home

- Products

- New Building Materials Machinery

- Wood Plastic Composite Production Line

Introduction of Wood Plastic Composite

With the feature of anti-acid, antiseptic, fireproof, waterproof and beautiful and elegant outlook, this building materials are becoming more and more popular all across the world and the market, now, has transferred from North America and EU to other countries. It is expected that WPC should replace pure wood in the near future. Moreover, WPC can be totally recycled and reproduced, dramatically reducing cost and influence on the environment.

Advantages of Wood Plastic Composite Production Line

Engaged in the WPC machinery industry for years, our company has organized an independent research team. The first class product quality, as well as the all round service, makes our customers feel secure to purchase the product from us.

1. The wood plastic composite production line comes with advanced design and first class quality. Our company has been granted several patents for this product.

2. Official certificate: CCC, CE, GOST, and ISO9001.

3. To ensure the quality of the machine, the screws and the machine barrel are produced from superior material and advanced technology, enabling the working life up to 15,000 hours.

4. Thanks to the PLC control system and the Omron sensors, the production process can be accurately controlled.

5. The accessories for the construction material machinery are all of international famous brand, like Siemens, Omron, ABB, etc.

6. Over 50% energy cost can be saved for the users with our wood plastic composite production line, compared with the product from other suppliers in China.

7. The raw material can be PP, PE, PVC, ABB and various wood powder and/or plant fiber.

8. This range of product has excellent mixing ratio. Under the control of some special formulas, over 70% of the wood powder can be added for production.

Technical Parameters of Wood Plastic Composite Production Line

| Item | HIM-WPC-80 | HIM-WPC-120 | HIM-WPC-200 |

| Capacity (kg/h) | 55-80 | 85-120 | 125-200 |

| Extruder Heating Power (kw) | 24 | 36 | 46 |

| Main Motor (kw) | 55 | 74 | 110 |

| Total Power (kw) | 91 | 124 | 199 |

| Size (L×W×H) (m) | 16×1.5×2.3 | 20×1.5×2.5 | 22×1.6×2.7 |

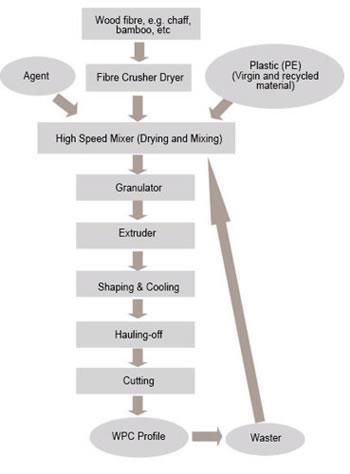

Flow Chart of Wood Plastic Composite Production Line

Wood fiber -> Fiber crusher dryer -> High speed mixer (Drying and mixing) -> Granulator -> Extruder -> Shaping and cooling -> Hauling off -> Cutting. And for the detailed information, please refer to the following chart:

Related Names

WPC Production Line

English

English Español

Español Русский

Русский Français

Français العربية

العربية