Aluminum Composite Panel (ACP) Production Line

- Home

- Products

- Metal Processing Machine

- Aluminum Composite Panel (ACP) Production Line

Introduction of Aluminum Composite Panel (ACP)

ACP is the abbreviation of Aluminum Composite Panel, which is composed of color aluminum sheet with polyethylene. With the obvious features of lightweight, perfect appearance, anti-corrosive, fireproof, and easy operation, it is widely used for the interior and exterior decoration.

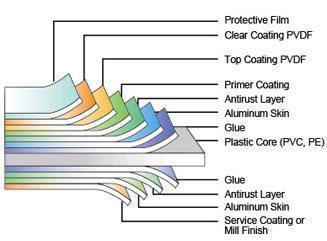

Structural Layer of Aluminum Composite Panel (ACP)

Aluminum Composite Panel includes several different structural layers which are as follows, and the detailed information please see the following chart:

(Here are layers from top top to bottom: protective PDF, clear coating PDF, top coating PDF, primer coating, antirust layer, aluminum skin, glue, antirust layer, aluminum skin, service coating or mill finish)

Features of Aluminum Composite Panel (ACP) Production Line from HiSuccess International

Based on our second-generation technology, this newly designed sheet panel machine is with the following obvious features:

• Energy saving

• Easy operating

• High pass rate

• Wide application

• Convenient maintenance

Application of Aluminum Composite Panel (ACP) Production Line

This line is more suitable for the producing the B1 grade fireproof panel. we also can provide Aluminum Pre-treatment Line, Aluminum Single Coating Line, and Aluminum Double Coating Line.

Main Configuration of Aluminum Composite Panel (ACP) Production Line

This ACP production line is composed of the following parts:

Extruding Part / Mold / Polishing Part / Macromolecule Felted-membrane Pre-compound Part / Lamination Part / Aluminum coil Uncoiling Part / Cooling Part / Protecting Film-covering Part / Traction Part / Panel Leveling Part / Automatic Measuring and Cutting Part / Electrical Control System

Technical Parameters of Aluminum Composite Panel (ACP) Production Line

| Item | Unit | Parameters | |

| Production Capacity (300 days/year, 20 hours/day) | m2 | 1,100,000 | |

| Aluminum Coil | Width | mm | 1250~1600 |

| Thickness | mm | 0.1~0.6 | |

| Max outer diameter | mm | 1300 | |

| Macromolecule Membrane | Width | mm | 1250~1600 |

| Thickness | mm | 0.03~0.05 | |

| Weight | Kg/coil | 60~80 | |

| Protecting Film | Width | mm | 1250~1600 |

| Thickness | mm | 0.06~0.08 | |

| Product | Width | mm | 1250~1600 |

| Thickness | mm | 0.06~0.08 | |

| Speed | m/min | 1~3 | |

| Total Power | kw | 640 | |

| Total Air Consumption | m3/min | 0.5~1 | |

| Total Water Consumption | mt/d | 1 | |

| Overall Dimension | m | 35×7×5 | |

| Total Weight | mt | 90 | |

English

English Español

Español Русский

Русский Français

Français العربية

العربية